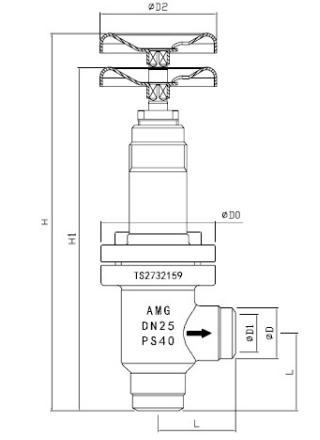

VCT15-80-D Forged Steel Right-angle Stop check Valve

Technical Parameter

Nominal pressure: 4.0MPa

Applicable temperature: -50℃~+150℃

Test pressure: 6.0MPa

Applicable medium: Ammonia, Freon, propane propylene etc.

|

Name |

Model |

Size (mm) |

Weight (kg) |

|||||

|

φD |

ΦD1 |

L |

ΦD0 |

H1 |

H |

|||

|

VCT Series Right-angle stop check valve |

VCT15-D |

21 |

15 |

40 |

65 |

190 |

210 |

1.3 |

|

VCT20-D |

25 |

20 |

40 |

65 |

190 |

210 |

1.4 |

|

|

VCT25-D |

32 |

25 |

51 |

75 |

227 |

253 |

2.4 |

|

|

VCT32-D |

38 |

32 |

51 |

75 |

227 |

253 |

2.5 |

|

|

VCT40-D |

45 |

40 |

60 |

95 |

276 |

313 |

4.2 |

|

|

VCT50-D |

57 |

50 |

64 |

95 |

276 |

313 |

4.3 |

|

|

VCT65-D |

76 |

65 |

75 |

105 |

316 |

362 |

7.4 |

|

|

VCT80-D |

89 |

80 |

80 |

115 |

335 |

386 |

8.2 |

|

Characteristics

● VCT series forged steel right-angle stop check valve, the moving part of the valve stem is equipped with high-precision double O-ring and PTFE packing, with perfect sealing performance and no leakage. All sealing gaskets are environment-friendly asbestos free gaskets.

● The rear seal design facilitates valve maintenance during system operation. The double cone seal design ensures large flow, small pressure drop and high efficiency. A special linkage structure is adopted between the valve stem and the valve disc, and the concentricity of the valve disc can be automatically adjusted to ensure the tightness of the valve closure and minimize the friction of the valve disc, thus extending the service life.

● The stop check valve can be directly welded to the steel pipe for convenient installation. Handwheel or sealing cover are optional. Each valve is checked in strict accordance with European standards.

For more details and different sizes, please contact us.