Thermojinn Water Chiller System (ICW&CW Series)

Thermojinn Water Chiller System Features and Advantages

● Special refrigeration system design and humanized automatic electrical system design ensure the normal and stable operation of the chiller under different working conditions.

● TLC series evaporative condenser, Special shape design, suitable for installation in containers. Double speed centrifugal fan, special-shaped coil design, efficient heat exchange effect, ensure stable and reliable operation of equipment.

● We adopt BITZER semi-hermetic piston and screw compressor, Germany. It is highly reliable. Service and components of BITZER compressor are available to you all around the world.

● The system adopts world famous brand refrigeration and electrical accessories. Ensure the high quality of equipment, facilitate maintenance, and easily obtain accessories locally.

● The evaporator adopts high-quality shell and tube type or plate exchange type, with high heat transfer coefficient, different water quality and easy maintenance.

● PLC fully automatic control, automatically adjust and control the compressor capacity according to the water temperature, improve efficiency and reduce energy consumption.

Main Fittings of Water Chiller

Evaporative Condenser

Thermojinn TLC Series Evaporative Condenser special design for Container installation.

● Modular design, convenient for installation and daily maintenance.

● Large heat exchange range , from 150kw to 1800kw.

● Double speed centrifugal fan, automatically adjusted according to the condensing pressure, with higher efficiency and lower energy consumption.

● The unique dimension design conforms to the container installation and transportation.

Compressor Unit

We adopt BITZER semi-hermetic piston and screw compressor, Germany. It is highly reliable. Service and components of BITZER compressor are available to you all around the world.

● World famous brand, Widely used worldwide.

● High cooling capacity and low energy consumption.

● Low vibration, low noise and stable operation.

● Simple operation and easy maintenance.

Shell & Tube and Plate Type Evaporator

Thermojinn water chiller shell and tube evaporator uses the latest efficient heat exchange copper tube with high heat exchange coefficient, ensuring good refrigeration performance of the unit and meeting different water quality requirements.

Thermojinn water chiller Plate type evaporator uses high quality stainless steel plate, special welding process. The cooling capacity channel inside the evaporator is smooth and the surface is smooth. Suitable for working conditions with large flow and low outlet water temperature.

Gauges and Control Components

All necessary refrigeration valves and gauges of the system, including shut off valve, pressure gauge, pressure controller, liquid sight glass, filter, solenoid valve, expansion valve, etc, which are all selected from world famous brand to guarantee most reliable equipment performance and longest lifespan. Any spare part is available at local market.

● World famous brand parts, easily available in the market.

● Precise control, improve efficiency and reduce energy consumption.

● Sensitive response to ensure stable operation of equipment.

● Easily realize automatic control and manual control switching.

Switches and Control Panel

Manufacture and wiring of electric system both strictly conform to the International Electrotechnical Commission(IlEC) standard. Moreover, it is equipped with best electric components available in market.

● The electric control system adopts international famous brands such as Siemens and Schneider.

● High quality, high precision, reduce equipment maintenance cost, and delay equipment service life.

● Fully automatic and precise control to improve the refrigeration performance of the system.

Containerized Assembly

The water chilling system is installed in a new 20/40 feet container. This container is painted white both inside and outside for screening sun. Inside, there are necessary illumination and air conditioning devices installed and aluminum plates floored on the bottom. Assembly, pipe line installation, wiring and pressure test of the water chilling equipment are all finished prior to delivery out of factory.

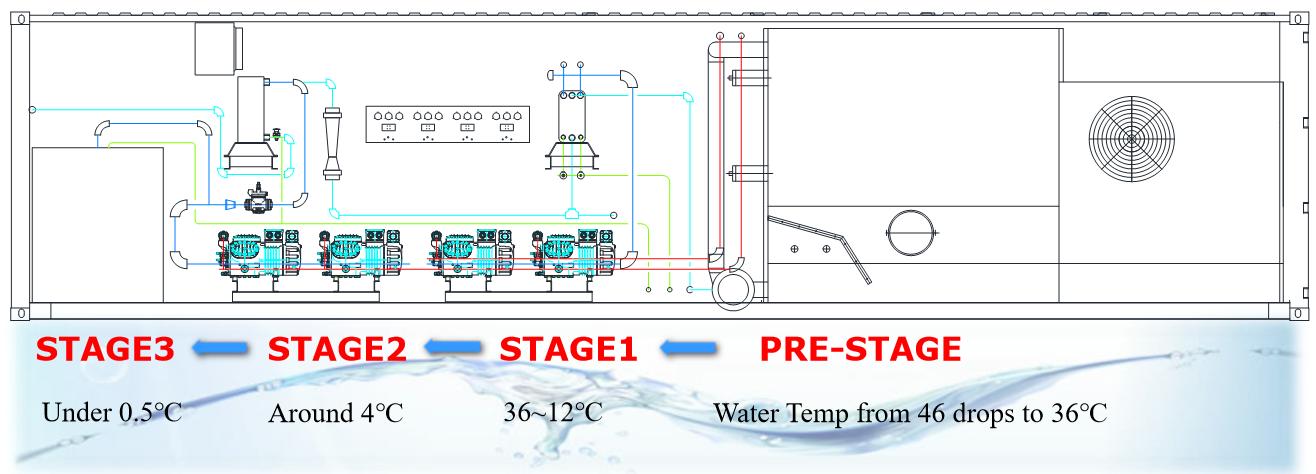

Water Cooling Procedure

1st cooling stage:

The raw water will be cooled down from 46℃ to 36℃,after entering the evaporative condenser,especially obvious in the middle east bay countries. Without starting the refrigeration system, the raw water js cooled down to 36℃ directly inside the evaporative condenser. It improves the efficiency of water chilling system.

2nd cooling stage:

Water temperature is cooled down from 36C to 12℃ inside the heat exchanger through the refrigeration of the 1st team of compressor.The heat exchanger is highly effective stainless steel plate type heat exchanger or shell and tube type heat exchanger.

3rd cooling stage:

In this stage, the water is cooled down from 12℃ to 4℃ inside the heat exchanger. The heat exchanger is highly effective stainless steel plate type heat exchanger or shell and tube type heat exchanger.

4th cooling stage:

In this last cooling stage,the water is cooled down from 4'℃ to 0.5℃ inside the specially made immersion type or falling film type heat exchanger. Inside the water tank, there are stainless steel plate heat exchanger and water and air distribution system to ensure constant water out temperature.

Backwater Cooling

Containerized ice water system is equiped with a backwater re-cooling system. When the water in the cold water tank has not been used for a long time, the water temperature will rise up to a certain temperature (can be set). And then the re-cooling system will start automatically to cool down the water temperature inside the cold water tank..

Thermojinn Ice Water Chiller System

Design Condition of TJ-ICW

Maximum temperature: +55℃ Power Supply: 380V/3P/50(60)HZ

Wet-bulb temperature: +30℃ Operating time: 24Hours

Water inlet temperature: +46℃ Refrigerant: R22/R404A/R507

Ice water outlet temperature:+0.5℃

Standard Configuration of TJ-ICW

1. Outside is standard white 20/40 feet new container;inside is

decorated with air conditioner, illumination and aluminum alloy floor ;

2. Refrigerating compressor unit is semi-hermetic screw or piston compressor:

3. Evaporative condenser with double speed fan;

4. The 1st and 2nd stage is highly effective stainless steel plate heat exchanger or shell and tube evaporator;

5. The 3rd stage is stainless steel immersion plate heat exchanger with air pump;

6. Necessary refrigeration system control, protect components and refrigeration pipeline connection;

7. Valves and sub-cooling back water pump of water line system inside with flow indication and low water flow alarm indication;

8. electrical control components and electric box with operator inter face for displaying the five stage water temperature;

9. Raw water tank and cold water tank level display are optional.

Containerized Ice Water Unit(TJ-ICW) Parameter

|

Model |

Unit |

TJ-ICW60 |

TJ-ICW 120 |

TJ-ICW 180 |

TJ-ICW 240 |

TJ-ICW 312 |

TJ-ICW 360 |

| Daily capacity |

Tons/day |

60 |

120 |

180 |

240 |

312 |

360 |

| Ice water flow |

m³/hr |

2.5 |

5 |

7.5 |

10 |

13 |

15 |

| Necessary Refrigeration |

kw |

124 |

260 |

390 |

520 |

675 |

780 |

| Installed Refrigeration |

kw |

139.1 |

289.4 |

441.9 |

571.7 |

725 |

815.4 |

| Installed Power |

kw |

36.8 |

66.1 |

97.6 |

121.6 |

165.8 |

196.8 |

| Running Power |

kw |

27.6 |

52.9 |

78.1 |

97.3 |

132.6 |

157.4 |

| System COP |

kw/kw |

3.99 |

4.13 |

3.87 |

4.14 |

3.68 |

4.15 |

| Container Specification |

ft |

20 |

20 |

40 |

40 |

40 |

40 |

| Water tank (supply by customer) |

m³ |

20 |

40 |

60 |

80 |

100 |

100 |

Containerized Ice Water Unit(TJ-ICW) Major Equipment

|

Model |

Container Size |

1st Stage Heat exchanger |

2nd Stage Heat exchanger |

3rd Stage Heat exchanger |

1st Stage Compressor |

2nd &3rd Stage Compressor |

Evaporative Condenser |

|

TJ-ICW60 |

20’FT |

Shell&Tube |

Shell&Tube |

Plate |

4NES-20Y |

4NES-20Y |

TVC45 |

|

TJ-ICW120 |

20’FT |

Shell&Tube |

Shell&Tube |

Plate |

6HE-35Y |

6HE-35Y |

TVC90 |

|

TJ-ICW180 |

40’HQ |

Shell&Tube |

Shell&Tube |

Plate |

6GE-40Y |

6HE-35Y |

TLC-650 |

|

TJ-ICW240 |

40’HQ |

Shell&Tube |

Shell&Tube |

Plate |

CSH7563-80Y |

CSH7553-70Y |

TLC-800 |

|

TJ-ICW312 |

40’HQ |

Shell&Tube |

Shell&Tube |

Plate |

CSH7573-90Y |

CSH7573-90Y |

TLC-1020 |

|

TJ-ICW360 |

40’HQ |

Shell&Tube |

Shell&Tube |

Plate |

CSH8553-110Y |

CSH8553-110Y |

TLC-1200 |

Thermojinn Cold Water Chiller System Details

Design condition of TJ-CW

Maximum temperature: +55℃ Power Supply: 380V/3P/50(60)HZ

Wet-bulb temperature: +30℃ Operating time: 24Hours

Water inlet temperature: +46℃ Refrigerant: R22/R404A/R507

Ice water outlet temperature:+4℃

Standard Configuration of TJ-CW

1. Outside is standard white 20/40 feet new container; inside is decorated with air conditioner, illumination and aluminum alloy floor;

2. Refrigeration compressor unit is semi-hermetic screw or piston compressor;

3. Evaporative condenser with double speed fan;

4. The 1st and 2nd stage is highly effective stainless steel plate heat exchanger or shell and tube evaporator;

5. Necessary refrigeration system control, protect components and refrigeration pipeline connection;

6. Valves and sub-cooling backwater pump of water line system inside with flow indication and low water flow alarm indication;

7. Electrical control components and electric box with operator interface for displaying the five stage water temperature;

8. Raw water tank and cold water tank level display are optional

Containerized Cooling Water Unit(TJ-CW) Parameter

|

Model |

Unit |

TJ-CW60 |

TJ-CW120 |

TJ-CW180 |

TJ-CW240 |

TJ-CW312 |

TJ-CW360 |

| Daily capacity |

Tons/day |

60 |

120 |

180 |

240 |

312 |

360 |

| Ice water flow |

m³/hr |

2.5 |

5 |

7.5 |

10 |

13 |

15 |

| Necessary Refrigeration |

kw |

110.8 |

221.7 |

332.5 |

443.3 |

576.3 |

665 |

| Installed Refrigeration |

kw |

118.3 |

232.3 |

349 |

466.5 |

603 |

697 |

| Installed Power |

kw |

27.3 |

53.9 |

82.2 |

111 |

154.8 |

157.9 |

| Running Power |

kw |

21.8 |

43.1 |

65.8 |

88.8 |

123.8 |

126.3 |

| System COP |

kw/kw |

4.3 |

4.3 |

4.2 |

4.2 |

3.9 |

4.4 |

| Container Specification |

ft |

20 |

20 |

40 |

40 |

40 |

40 |

| Water tank (supply by customer) |

m³ |

20 |

40 |

60 |

80 |

100 |

100 |

Containerized Cooling Water Unit(TJ-CW)Major Equipment

|

Model |

Container Size |

1st Stage Heat exchanger |

2nd Stage Heat exchanger |

1st Stage Compressor |

2nd Stage Compressor |

Evaporative Condenser |

|

TJ-CW60 |

20’FT |

Shell&Tube |

Shell&Tube |

4NES-20Y |

4PES-15Y |

TVC45 |

|

TJ-CW120 |

20’FT |

Shell&Tube |

Shell&Tube |

6HE-35Y |

6GE-30Y |

TVC90 |

|

TJ-CW180 |

40’HQ |

Shell&Tube |

Shell&Tube |

6GE-40Y |

6GE-30Y |

TLC-650 |

|

TJ-CW240 |

40’HQ |

Shell&Tube |

Shell&Tube |

CSH7563-80Y |

CSH7563-60Y |

TLC-800 |

|

TJ-CW312 |

40’HQ |

Shell&Tube |

Shell&Tube |

CSH7573-90Y |

CSH7583-80Y |

TLC-1020 |

|

TJ-CW360 |

40’HQ |

Shell&Tube |

Shell&Tube |

CSH8553-110Y |

CSH7583-100Y |

TLC-1200 |

* Heat Exchanger have stainless steel plate or Shell&tube type optional.

* Parameters may change due to equipment upgrade without notice.