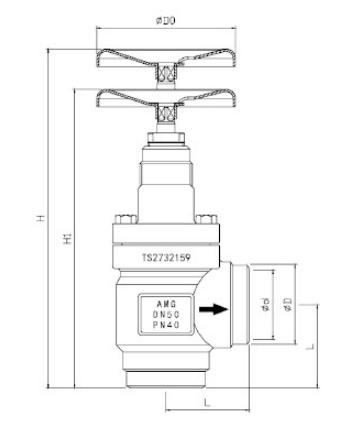

STT15-150-D Forged steel right-angle stop valve

Technical Parameter

Nominal pressure:2.5MPa

Applicable temperature: -50℃~+150℃

Test pressure: 3.75MPa

Applicable medium: Ammonia,Freon, propane propylene etc.

|

Name |

Model |

Size (mm) |

Weight (kg) |

||||

|

φD |

L |

H1 |

H |

ΦD0 |

|||

|

STT Series Right-angle stop valve |

STT15-D |

21 |

35 |

135 |

150 |

60 |

0.55 |

|

STT20-D |

27 |

45 |

155 |

170 |

60 |

1 |

|

|

STT25-D |

34 |

45 |

155 |

170 |

60 |

1.1 |

|

|

STT32-D |

42 |

51 |

180 |

205 |

80 |

1.9 |

|

|

STT40-D |

48 |

55 |

195 |

225 |

80 |

2.3 |

|

|

STT50-D |

57 |

60 |

215 |

240 |

100 |

3.4 |

|

|

STT65-D |

76 |

70 |

240 |

275 |

120 |

5.3 |

|

|

STT80-D |

89 |

90 |

280 |

315 |

160 |

8.6 |

|

|

STT100-D |

108 |

106 |

325 |

375 |

180 |

13.5 |

|

|

STT125-D |

133 |

128 |

395 |

460 |

200 |

27 |

|

|

STT150-D |

159 |

145 |

460 |

545 |

250 |

37 |

|

Working Principle

Forged steel stop valve is the most widely used valve. The reason why it is widely popular is that the friction between sealing surfaces is small, relatively durable, the opening height is small, easy to manufacture, and easy to maintain. It is not only suitable for medium and low pressure, but also for high pressure. Its closing principle is to make the sealing surface of the valve clack and the sealing surface of the valve seat closely fit with the pressure of the valve rod to prevent the flow of medium. Forged steel stop valve only allows one-way flow of medium and has directionality during installation.

Characteristics

1. The valve body is integrally forged with high strength, beautiful shape and reliable material.

2. The middle chamber adopts self-sealing structure. The higher the pressure, the better the sealing. The unique stainless steel self-sealing ring is convenient for disassembly and reliable for sealing.

3. The surface of the valve rod is treated with ultra-dense wear-resistant treatment, wear-resistant and corrosion-resistant, and the opening and closing friction is small, ensuring that the product is free from leakage.

For more details and different sizes, please contact us.