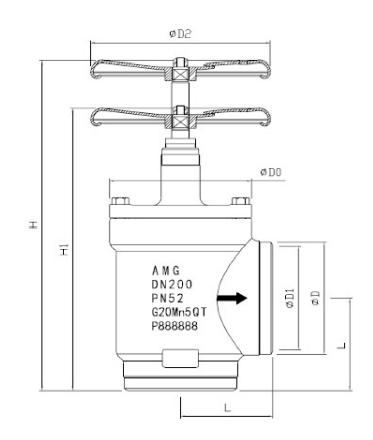

RVT100-300-D Cast Steel Right-angle Stop Valve

Technical Parameter

Nominal pressure: 4.0MPa

Applicable temperature:-50℃~ +150℃

Test pressure: 6.0MPa

Applicable medium: ammonia,fluorine, propane, propylene, etc.

|

Name |

Model |

Size (mm) |

Weight (kg) |

||||

|

φD |

L |

φD0 |

H1 |

H |

|||

|

RVT Series Right-angle Stop Valve |

RVT100-D |

108 |

106 |

156 |

325 |

375 |

19 |

|

RVT125-D |

133 |

128 |

193 |

395 |

460 |

28 |

|

|

RVT150-D |

159 |

145 |

219 |

460 |

545 |

38 |

|

|

RVT200-D |

219 |

180 |

276 |

550 |

645 |

78 |

|

|

RVT250-D |

273 |

210 |

334 |

620 |

725 |

145 |

|

|

RVT300-D |

325 |

240 |

384 |

655 |

760 |

288 |

|

Working Principle

-The working principle of cast steel stop valve is to make the valve unblocked or blocked by rotating the valve. The gate valve is portable, small in size, can be made into a large diameter, reliable in sealing, simple in structure and convenient in maintenance. The sealing surface and spherical surface are often closed, and are not easy to be eroded by media. It is widely used in various industries.

-The sealing pair of the stop valve consists of the sealing surface of the valve disc and the sealing surface of the valve seat. The valve rod drives the valve disc to move vertically along the center line of the valve seat. During the opening and closing process of the stop valve, the opening height is small, the flow is easy to adjust, the manufacturing and maintenance are convenient, and the pressure is applicable to a wide range.

-The sealing surface of the stop valve is not easy to wear and scratch, and there is no relative sliding between the valve disc and the sealing surface of the valve seat during the valve opening and closing process, so the wear and scratch on the sealing surface is small, so the service life of the sealing pair is improved. The stop valve has a small stroke of the valve disc during the full closing process, and its height is relatively small.

Characteristics

1. Open and close without friction. This function completely solves the problem that the sealing of traditional valves is affected by the friction between sealing surfaces.

2. Top-mounted structure. The valve installed on the pipeline can be directly inspected and maintained online, which can effectively reduce the shutdown of the device and reduce the cost.

3. Single seat design. It eliminates the problem that the medium in the valve cavity affects the use safety due to abnormal pressure rise.

4. Low torque design. The valve rod with special structure design can be opened and closed easily with only a small handle valve.

5. Wedge sealing structure. The valve is sealed by pressing the ball wedge onto the valve seat with the mechanical force provided by the valve stem, so that the sealing performance of the valve is not affected by the change of the pipeline pressure difference, and the sealing performance is reliably guaranteed under various working conditions.

6. Self-cleaning structure of sealing surface. When the ball is tilted away from the valve seat, the fluid in the pipeline passes through the valve seat at 360 ° along the sealing surface of the ball, which not only eliminates the local scouring of high-speed fluid on the valve seat, but also washes away the accumulation on the sealing surface to achieve the purpose of self-cleaning.

7. The valve body and bonnet with the valve diameter below DN50 are die forgings, and the valve body and bonnet with the valve diameter above DN65 are steel castings.

8. The connection forms of valve body and bonnet are different, including clamp pin connection, flange gasket connection and self-sealing thread connection.

9. The sealing surfaces of the valve seat and the valve disc are made of plasma spray welding or hard facing cobalt chromium tungsten carbide, with high hardness, wear resistance, scratch resistance and long service life.

10. The valve rod is made of nitrided steel. The surface hardness of the nitrided valve rod is high, wear-resistant, scratch resistant, corrosion resistant and long service life.

For more details and different sizes, please contact us.