Project Base:Refrigeration project & Concrete cooling project

Classification of cold storage

1. Classified by capacity and scale of cold storage: large cold storage, medium cold storage, small cold storage;

2. Classified according to the design temperature of refrigeration: high-temperature cold storage (constant temperature storage), medium-temperature cold storage (cold storage), low-temperature cold storage (cold storage), ultra-low-temperature cold storage (deep cold storage), quick-frozen storage (quick-frozen storage);

3. Classification according to the structure category of the warehouse: civil cold storage, storage of frozen goods. Earth-covered cold storage, cave cold storage, combined plate cold storage;

4. Classified by nature of use: production cold storage, distribution cold storage, retail cold storage;

5. Classification of refrigerants in cold storage

Ammonia cold storage: The refrigeration system uses ammonia as the refrigerant.

Freon cold storage: a cold storage where Freon is used as refrigerant in the cooling system.

6. Classified according to the use and storage characteristics: supermarket cold storage, constant temperature cold storage, air-conditioned cold storage, double temperature cold storage;

7.Classified by storage items: medicine cold storage, meat cold storage, blood cold storage, vaccine cold storage, fruit cold storage, medicine cold storage, aquatic products cold storage

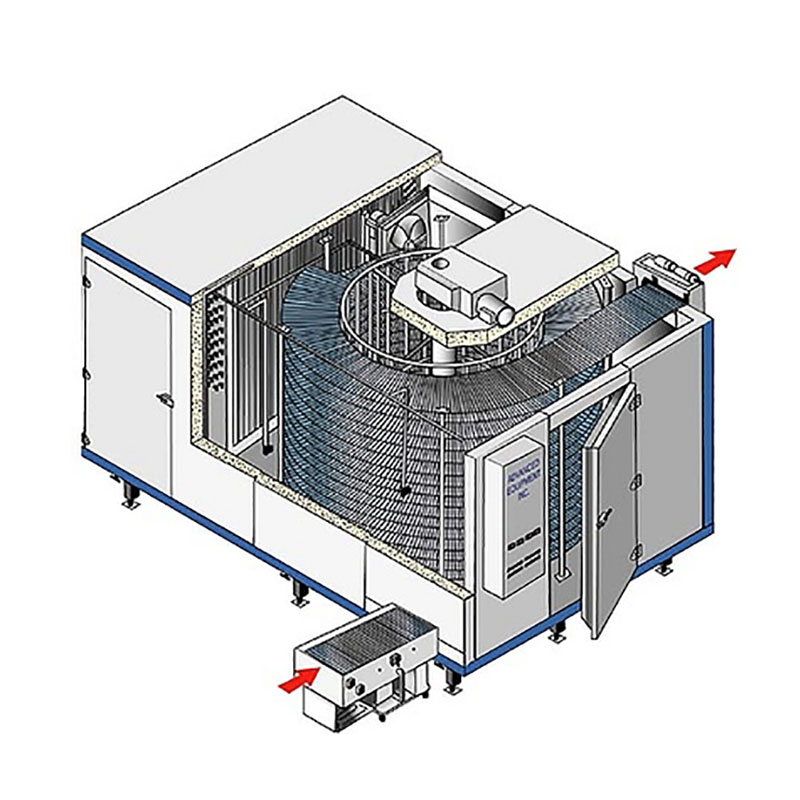

Concrete cooling system project

The concrete cooling system is divided into front and rear cooling systems, which are generally composed of multiple subsystems and work together. When the neutron system includes: cold water system, ice maker system, ice storage and delivery system, ice delivery system, and weighing system.

1.The cold water chiller system is the most important for the whole cooling system. Through the cold water system, the hot water with a temperature of more than 45 ℃ can be reduced to 0.5 ℃ after four steps of cooling, which is the best suitable temperature for concrete activity.

2.The concrete cooling system needs a large amount of ice that can be rapidly cooled as the cooling medium. Sheet ice and plate ice are widely used in concrete cooling systems because of their largest surface area per unit ton, best cooling effect and largest output, among which the sheet ice system is the best.

3.The ice storage system is located under the ice making system, and the top is connected with the opening of the ice making system. The ice storage system is installed in the container, with the storage capacity ranging from 20 tons to 200 tons. Since the ice inlet is fixed on one side of the container, it is often necessary to equip additional devices to equalize the ice storage capacity of the container, generally including rake type and crawler type.

4.The ice in the ice delivery system is discharged from the ice outlet on one side, and transported horizontally or lifted to the weighing operation place through the ice delivery system installed at its bottom. The ice delivery system can be divided into screw ice delivery system, gas ice delivery system and hybrid ice delivery system according to its structure and principle.

5.The ice weighing system measures the weight of ice delivery through the weighing mechanism and accurately controls the mixing temperature of concrete.